|

|

||||||||||||||||||||||

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

|

|

|

||||||||||||||||||||

|

|

|||||||||||||||||||||

|

23 August 2002

|

||||||||||||||||||||||

|

|

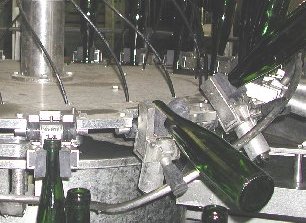

The varieties that were bottled that day were: Grand Cru Zinnkoepflé Riesling,Tokay and Gewurztraminer, The Noble Valley late harvest Tokay and Gewurztraminer, late harvest Grand Cru Zinnkoepflé Riesling. |

|||||||||||||||||||||

|

|

The operations: |

|||||||||||||||||||||

|

||||||||||||||||||||||

|

||||||||||||||||||||||

|

6. The bottles continue their way to a resting bay where they stay for a few minutes so that the corks have the time to return to their original diameter. This has to be done so that the bottles become watertight for later handling operations. A big visible-to-all meter records the number of corked bottles to be able to determine the cost of the filling operation (6 euro centimes per bottle plus a fixed amount for the filtering). |

||||||||||||||||||||||

|

|

||||||||||||||||||||||

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||